Spiral Wound Gasket

● Attractive Price

● Strong Delivery

● Quality -Forever

● Attractive Price

● Strong Delivery

● Quality -Forever

High - Quality Spiral Wound Gaskets with Epoxy Coating: Your Ideal Sealing Solution for Clean Environments

We adhere to strict quality control measures throughout the manufacturing process. Each gasket is carefully inspected to ensure it meets or exceeds industry standards. From the precision winding of the metal and filler materials to the flawless application of the epoxy coating and Teflon layer, every step is carried out with meticulous attention to detail.

Customer testimonials speak volumes about the quality of our products. Many clients in industries such as food processing and medical device manufacturing have reported that our Spiral Wound Gaskets with Epoxy Coating have significantly improved the efficiency and cleanliness of their operations. They have experienced fewer leaks and contaminations, leading to enhanced productivity and reduced downtime.

In conclusion, if you're in search of a high - quality gasket that can perform flawlessly in clean environments, look no further than our Spiral Wound Gaskets with Epoxy Coating. With their superior construction, advanced features, and proven track record, they are the ultimate choice for all your sealing needs.

|  |  |  |

|  |  |  |

GENERAL NOTES

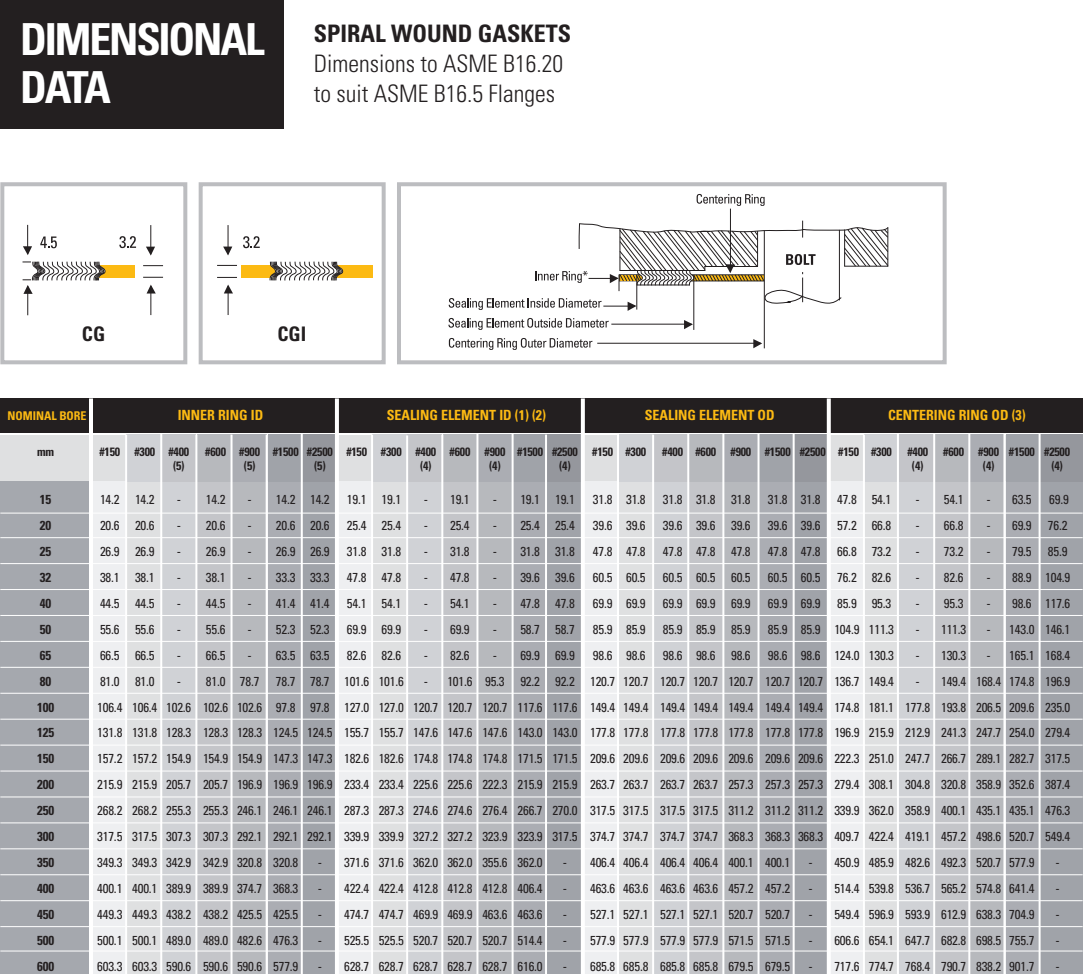

All dimensions are in mm.

Figures stated are for information only. Please refer to the current version of the original standards for dimensional information.

The gasket thickness tolerance is +/- .13 mm measured across the metallic portion of the gasket, not including the filler, which may protrude slightly beyond the metal.

The inner-ring thickness shall be 2.97mm to 3.33mm.

For sizes NPS ½ through NPS 3, the insider diameter tolerance is +/- 0.8mm; for larger sizes the inside diameter tolerance is +/- 1.5mm.

NOTES

1. The gasket outside diameter tolerance for NPS ½ through to NPS 8 is +/-0.8mm; for NPS 10 through NPS 24 +1.5mm -0.8mm

2. The gasket inside diameter tolerance for NPS ½ through to NPS 8 is +/-0.4mm; for NPS 10 through NPS 24 +/- 0.8mm

3. The centering ring outside diameter tolerance is +/-0.8mm

4. There are no Class 400 flanges in NPS ½ through NPS 3 (use Class 600), Class 900 flanges in NPS ½ through NPS 2 ½ (use Class 1500), or Class 2500 flanges NPS 14 and larger

5. There are no NPS ½ through NPS 3 Class 400 flanges (use Class 600), NPS ½ through NPS 2 ½ Class 900 flanges (use Class 1500), or NPS 14 and larger Class 2500 flanges

FAQ

Q1:You are a trading company or manufacturer?

A:We are manufacturer with more than 20years production experience, and have our own factory in HeBei.

Q2:Can you provide OEM service?

A:Yes, welcome.

Q3:Can you send me a sample? Is it free?

A:Yes, the samples is free, but the courier charge should be on your side.

Q4:The price that you offer me, Could be more discount?

A:It will depend on order quantity.

Q5:ls there any warranty, can exchange it?

A:Normally our warranty period is three months. If it is quality problem, we support a replacement, refun buyer bears the two freight back and forth.

Q6:Mode of transportation

A:By sea or by air.

Q7:what the quality of the products?

A:Customer's feedback says quality is very good!

Q8:How about the Delivery time?

A:Normally 15-35 days after receiving the 30% deposit. Samples will be prepared within 5 Days.